Search

Recent comments

- google bias...

24 sec ago - other games....

3 min 37 sec ago - נקמה (revenge)....

1 hour 3 min ago - "the west won!"....

3 hours 6 min ago - wagenknecht......

3 hours 47 min ago - the game of war....

6 hours 12 min ago - three packages....

7 hours 32 min ago - russian oil.....

7 hours 39 min ago - crime against peace....

15 hours 51 min ago - why is Germany supporting the ukrainian nazis?....

17 hours 3 min ago

Democracy Links

Member's Off-site Blogs

the things-that-are...

In Anaxagoras' philosophical views, the mechanism for the apparent coming-to-be is mixing and separating out from the mixture, produced by the vortex motion of the ingredients. Through this mechanism, the real things, the ingredients, can retain their character throughout. When an arrangement breaks apart, the ingredients are dissociated from one another and can be re-mixed to form different arrangements, or other perceptible objects.

Anaxagoras’ main point is that animals, plants, human beings, the heavenly bodies, are natural constructs. They depend for their existence and character on the ingredients of which they are constructed and they acquire a specific pattern in the process. Yet they are natural because their construction occurs as one of the processes of nature. Human-made artefacts which are similarly constructs of ingredients, are not such naturally determined to fulfil some purpose. This is to say that Anaxagoras had no god in his formulation of existence.

Things such as earth, water, fire, hot, bitter, dark, bone, flesh, stone, or wood are basic and genuinely real: they are things-that-are.

Human-made objects constituted by these ingredients are not genuinely real, they are temporary mixtures with no autonomous status: they are not things-that-are. They are transient (even “plastics” — see comment).

This view, that the ingredients are more real than the objects that they make up, is common in Presocratic philosophy, especially in the theories of those thinkers who were influenced by Parmenides’ arguments against the possibility of what-is-not. It can be found in Empedocles and in the pre-Platonic atomists, and to a point, in Plato’s Theory of Forms.

These enlightened philosophical views soon (±300 AD) became distracted by monotheistic religious beliefs for imperial political expediency. Even the flexible adventures of the Greek/Roman gods became myths to be replaced by a singular rigid myth.

Monotheistic Religious beliefs are based on static imagination.

This is how it is. It’s written in this big book: believe or you’re going to hell. In the temporal world, this became manifested by the infliction of physical pain. People were tortured to make them recant disbelief. The inquisition of the Catholic Church was a fierce example of this stupidity in the degradation of the philosophical thought.

Presently, most of Islam religious rulers also inflicts physical pain and death to those who do not believe. Ridiculous and unacceptable.

Sciences and philosophies thus became sterile and no progress nor observations were allowed. The theories of Anaxagoras (about 500 BC) and of the Atomists were forgotten, but some people were secretly still asking questions.

We all know (we all should) of da Vinci doing his dissections and drawings thereof proving that humans had the same structure as other animals — all against the expressed interdictions of the Church. On this subject alone he’s a far more important artist/investigator than Michelangelo who was a mercenary doing the Church bidding with his magnificent art.

Johannes Kepler, a German astronomer, mathematician, astrologer was a key figure in the 17th-century scientific revolution. He is best known for cosmic laws and calculations that provided some of the foundations for Newton's theory of universal gravitation.

After Copernicus, Kepler and Galileo had more or less reverted to (or unknowingly rediscovered) the understanding by the ancient Greeks of the cosmos, contrarily to the religious teachings, Newton applied some mathematics to the motion of the celestial bodies. Newton would have been considered a heretic, had it been found that he was a non-believer in the Trinity — an important tenet of Christianity. Newton's maths though were a tad wonky and to make things work he included “the hand of god” in the system.

Mathematics are structured imaginings. Maths are imagination in reason and logic and evolving along these lines as well as peering into divergent thinking. At the beginning of the 19th century, Laplace reworked Newton’s work and remove “the hand of god” from it. Napoleon asked one of his confident: “Is Laplace an atheist?”. The confident replied: “One does not know… but he certainly does not believe in god.”

Then came some important mathematicians who still rattle our simple minds: Lagrange, Poincaré, and some philosophers who sorted out the individual psyche such as Freud and Jung — and some who reworked the social contract such as Marx and Engels… We were on the path of intelligent discourses, in which slavery and floggings of workers were to become a thing of the past.

But the Religious conservatives, were still pushing for “less understanding and more beliefs”. They still do under various guises, including the evangelicals, and by whatever luck for them and bad luck for us, they tend to always end up at the control of the social equation, like a “Big Brother". Their tools are ignorance, static imagination and money. I will venture to say that wars are also part of their vicious way to control the loot, while making us “believe in democracy”, which at this stage is still a frayed monkeys’ dream.

Sciences and mathematics though had made an alliance to spur imagination beyond what we knew to keep beliefs at bay.

The theory of relativity, in which time, space, energy and matter are interdependent, was postulated by Einstein. As well, Atomist philosophy had re-entered the discourse and made massive strides with the concept of Quantum Physics. Without any of these theories that understand the things-that-are and the processes that make-them-to-change, we would not have the atomic bombs nor cell phones.

Until the theory of black holes.

The first inkling of the existence of such bodies was made by the said Laplace in the 19th century. But the maths were beyond mere mortals until Stephen Hawkins. Black holes are tiny spaces in which gravity, a very weak force in relation to time, becomes so strong by accumulation, that nothing can escape it. Matter, energy, space and time become extremely compressed, basically destroying everything, beyond a so-call event horizon, the border where things still are — and where they’re not in the black hole.

This led to a massive conundrum. The information paradox. With Lavoisier’s experiments we had postulated that “nothing is lost, nothing is created, everything is transformed”. Then came along the realisation that in a radioactive reaction, we were loosing matter and the postulate of Lavoisier became shaky. Looking at the problem more closely, some of the original elements had transformed into new ones, releasing energy which at first was not counted — hence the “loss” of something. When accounted and measured, this energy was found to be wave/particles or particle/waves such as light — or photon — or gamma rays, etc that was equalled to the material loss. At this stage we had confirmed the equivalence of energy and matter so elegantly expressed by Einstein E = m x c(squared).

In a basic nuclear explosion, only a fraction (about 0.16 gram) of several kilograms of matter becomes energy. This is our human-made sunlight. This transformation of matter into energy can be massively destructive.

Meanwhile, the theory of black holes was pushing us back to reconsider “nothing is lost, nothing is created, everything is transformed” because when looking at matter, time, space and energy — everything is “information”. Information was lost inside the black holes. This is the "information paradox".

In short, in order to solve this paradox, Hawkins revised his maths and later in his life, could let us know that the “information” was retained at the event horizon and that black holes could release energy, an energy which recaptured the info when going in reverse through the event horizon. This seems to be like a convenient gymnastic, but in reality, we had to accept that black holes had their own internal limits, otherwise the entire universe would disappear into them, which it does nonetheless with entropy towards the greater nothingness.

Meanwhile on this little planet, the Religious Conservatives, still deny the relative mechanics of its limited surface. Humans could not do anything wrong as long as they subscribed to the moralistic dictums: ignorance of scientific evidence, static imagination in beliefs, the accumulation of money as a thing-that-is which-it-is-not, and wars.

Under the unenlightened guidance of Religious Conservatives, global warming will wipe our "derrière". Please, excuse Jules Letambour’s French.

Gus Leonisky

Atheist.

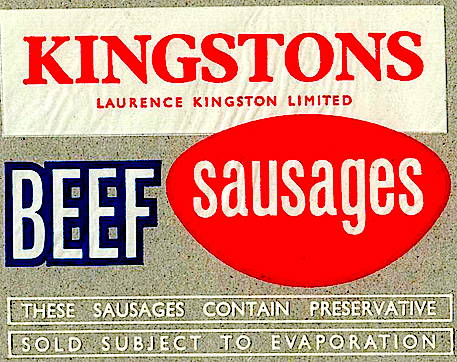

Picture at top: an early 1960 example of printing on thin cellulose film using Flexographic printing. Sausage wrapper printed in three colours.

- By Gus Leonisky at 11 Jan 2020 - 9:13am

- Gus Leonisky's blog

- Login or register to post comments

the plastic sea...

Made by humans, plastics are unfortunately things that are very close to the "things-that-are” but unnaturally forever… Although plastics can be physically broken up, they are extremely difficult to break up chemically. Plastics are thus a massive problem because of these conflicting properties. They can break up in smaller bits, but not readily in elementary bits.

We all have (we should have) experienced buying a machine where the plastics bits and the engine are extremely sturdy. But a stupid engineer or a lazy manufacturer, possibly a cheap subcontractor, has designed a small piece that will break soon after the warranty runs out. It’s either inbuilt obsolescence, badly designed or cheap carelessness to save a tiny amount of cash by using polypropylene instead of polycarbonate. Say a food processor, with a thousand perfect bits becomes unusable because a small prong, made of cheap plastic, becomes too weak to sustain its function, the MOST IMPORTANT IN THE OPERATION OF THE MACHINE: a safety device that does not allow operation should the lid not be placed on top. This simple prong is no more than 10 mm long and, broken, the whole machine becomes unusable.

Spare parts? In what universe are you living? The repair and replacement of the part cost twice as much as the machine in its original cardboard box, without counting the driving time to the wholesalers, because more often than not, the retailers decline responsibility, once the warranty — which you could have extended by another three years by paying an extra $50 — has run out. Even if the warranty is still valid, your machine is out of action for at least a month, and the part that broke is replaced by another one that will break soon enough.

Often, people will discard the broken down machine, get another one. It’s cheaper. The landfill is full of this stuff, unless you take it to the Bower in Marrickville, where dedicated staff can repair it for a sum “you can afford”. Or you can fix it yourself if you can be bothered.

The person(s) who discovers a way to destroy plastics into elementary bits is likely to become the most important person on the planet since Hawkins, Einstein and Newton combined.

Plastics have become the new invasive species. Though inanimate, most plastics are derivatives of biochemistry of the fossil fuel industries. Plastics have made Dupont and the Koch industries super-rich, yet they take no responsibility in the disposal nor the destruction thereof.

Not only becoming the major parts of landfill, plastics invade the seas and become killers of nature.

The list of destruction and pollution is long.

Sea birds are ingesting plastic bits

Other sea animals, like turtles, are ingesting plastic.

Stomach acids do not destroy plastics.

Some bacteria break up some plastics — but very slowly.

Micro-plastics have entered the food chain.

Plastic micro beads are used in some toothpaste and other products.

Some of the additives in plastics change metabolic functions

"Biodegradable” plastics are a misnomer as they only break up in micro-plastic size bits.

Some plastics are not sun resistant and the polymers break up in smaller bits.

Polyethylene and Polystyrene are major culprits in the food chain.

Nylons are culprits in the entanglement of marine life such as whales, etc...

We have already mentioned some of these at: and ….

But even since then, the problems have compounded. Some people are already mentioning that by 2050, the “plastic" problem will 500 times worse than it is now… with no “solution" in sight. Even the machines that are designed to clean up the waterways are struggling to a collect tiny fraction of what plastic rubbish there is.

So, what do we do?

Can we live without plastics?

Our industrialisation has been a boon. We may not be able to live without plastics, steel, copper, nor gold in all its values — from ingots to electronics. The main problem is about the value of plastic. And we’re not talking about your credit card(s). PLASTICS ARE VERY CHEAP TO MANUFACTURE and the throwaway society was born. This is the main point. Throw away goods ARE NOT NEW, but from rotten food to wooden crates, they used to break up back into elementary bits. Plastics don’t. Thus the answer to our major problem is not to throwaway plastics, to find a way to break them up in elementary particles and to manufacture far less of them — making them more valuable.

As well, there are some equivalent that can be used for packaging. Cellophane, which is a wood based product can disintegrate over time… Other new products developed in Indonesia is the algae based packaging. For a long time we had the transparent rice paper… Printing on these can sometimes be a challenge, unlike printing on plastic wrappers…

Recycling is a major headache as well. Many warehouses get filled with "recyclable plastics" that never end up being "recycled". Recycling plastics into new products is very difficult, even microfined and compressed to make fake planks. Most plastics do not combine with a "different" sort of plastic. Some new binders have been developed but it's still at experimental stage and costly.

For some plastic products, alternative materials are available.

NATUREFLEX™ - COMPOSTABLE AND RENEWABLE PACKAGING FILMS

NatureFlex™ is a range of speciality packaging films developed by Futamura to offer packaging material options that give strong environmental support towards increasing consumer demand for more environmentally responsible packaging. These bio-films are based strongly on renewable resources (wood-pulp from managed plantations) and are certified to the European (EN13432) and American (ASTM D6400) norms for Industrially compostable packaging. In addition, the majority of grades have been certified by TÜV Austria to the OK Compost Home standard for home composting and certain grades have been proven to biodegrade in a waste-water environment. Further testing has proven that most NatureFlex™ grades are also suitable for anaerobic digestion.

To further support the positioning of NatureFlex™, a peer reviewed LCA has been carried out by Thinkstep, based on their GaBi software, allowing transparent communication of the environmental impacts of using these films.

NatureFlex™ films use novel heat seal-resins on each side. They are static free and offer a super wide heat seal range for outstanding machine performance. The films offer good gas barrier properties and the coatings can be tailored to provide varying degrees of moisture barrier, depending on the needs of the wrapped product.

Four aspects for the development of these films have been vital to ensure that each product performs technically and environmentally:

http://www.futamuragroup.com/divisions/cellulose-films/products/natureflex/

Recycling is a major headache as well

Cellulose Film Packaging Gains Popularity with Plastic Reduction Initiatives

BY AXEL BARRETT

February 22, 2019

The Research Institutes of Sweden has prototyped cellulose film based containers for food items such as cup soups, which stretch into compostable bowls on the addition of hot water, which provides new opportunities for major retailers such as the UK’s Iceland and the Netherland’s Ekoplaza, that are aiming towards zero-plastic in the near future.Cellulose film packaging material is being increasingly used in the form of pouches or bags in end use industries such as personal care and food & beverage. The growth of the cellulose film packaging market can be largely attributed to the issues arising from the indiscriminate use and disposal of plastic items such as bags, bottles, boxes and more.

With growing awareness about environmental concerns, the biodegradable nature of cellulose film has made it an ideal choice in the development of sustainable solutions for packaging, with the aim of reducing the overall carbon footprint of the packaging industry.

Bio-based Nano-Composites of Cellulose Attracts Attention

Materials based on biopolymers have rapidly gained interest in recent times for the role of plastic alternatives, for increased activity in the development of sustainable materials, for packaging. Materials derived from plants such as cellulose are currently undergoing extensive research, for improvements in active biodegradability.

Biodegradation Analyzers & Measurements in Compost, Water and Algae

On the other hand, cellulose films are restricted from extensive industrial use owing to limitations in the barrier and mechanical characteristics of the material in comparison to conventional plastic. Moreover, biopolymers such as cellular films are also restricted by their poor resistance to moisture. However, these issues are expected to be circumvented through the development of nano-composite technology.

For example, the nanocomposite of carboxymethylcellulose sodium is made using the combination of carboxymethylcellulose sodium with zinc oxide, which displays significant improvements in tensile strength and elasticity, along with notable reduction in the permeability of water vapor.

Cellulose films are also finding widespread application in the food industry as edible packaging materials. This is particularly true of hydroxypropyl methylcellulose, which makes use of chitosan nanoparticles to improve on physical properties, to reduce the penetration of carbon dioxide, oxygen and more, boosting the prospects of the cellulose film packaging market.

Sustainability Activities Drive Innovations in Cellulose Film Materials

With the growing importance given to sustainability practices renewable bio-plastic materials have been developed from numerous sources including corn, wheat, and potatoes among others. However, cellulose based films are gaining popularity owing to its easy availability and abundance in nature. Packaging businesses are focusing their efforts on material improvements to meet a wider scope of packaging needs.

For example, NatureFlexTM by Futamura has developed cellulose film packaging materials that are resistant to oils and fats, with the use of heat-seal resins that makes the material safe for use in microwave or oven applications. The cellulose is derived sustainably harvested wood pulp, and can comprise up to 99% of bio-based materials.

Moreover, the company has tied up with Bio4Pack by combining cellulose based Tipa and NatureFlex films, which are being used as packaging for food items aimed towards the growing presence of plastic-free aisles in the retail market.

Read more:

https://bioplasticsnews.com/2019/02/22/cellulose-film-packaging-gains-po...

See also:

https://www.bbc.co.uk/programmes/b0bmbn47...

anaxagoras' mulitverses...

Since these things are so, it is right to think that there are many different things present in everything that is being combined, and seeds of all things, having all sorts of forms, colors, and flavors, and that humans and also the other animals were compounded, as many as have soul. Also that there are cities that have been constructed by humans and works made, just as with us, and that there are a sun and a moon and other heavenly bodies for them, just as with us, and the earth grows many different things for them, the most valuable of which they gather together into their household and use. I have said this about the separation off, because there would be separation off not only for us but also elsewhere.

Read more:

https://plato.stanford.edu/entries/anaxagoras/

see also:

http://www.yourdemocracy.net.au/drupal/node/33567

http://www.yourdemocracy.net.au/drupal/node/28993

http://www.yourdemocracy.net.au/drupal/node/12048

and

http://www.yourdemocracy.net.au/drupal/node/30319

http://www.yourdemocracy.net.au/drupal/node/35460

the mystery of "something is lost" in sausages...

In the image at top, the line "subject to evaporation" could intrigue the smart investigator. In order to understand that "nothing is lost" (except that the sausages weigh less), the packaging may allow some of the moisture of the product to escape into the atmosphere. Cellophane may not be as air-thight as plastic packaging. Hence the fair warning "subject to evaporation" ...

https://books.google.com.au/books?id=5oE1VWm2lXoC&pg=PA139

If you remember Yes Minister, you would have seen the episode about the "British Sausage" and the European "common market" — an episode that may have led to Brexit...

by the numbers...

————————————

PET is one of the most commonly used plastics in consumer products, and is found in most water and pop bottles, and some packaging. It is intended for single use applications; repeated use increases the risk of leaching and bacterial growth. PET plastic is difficult to decontaminate, and proper cleaning requires harmful chemicals. Polyethylene terephthalates may leach carcinogens.

PET plastic is recyclable and about 25% of PET bottles in the US today are recycled. The plastic is crushed and then shredded into small flakes which are then reprocessed to make new PET bottles, or spun into polyester fiber. This recycled fiber is used to make textiles such as fleece garments, carpets, stuffing for pillows and life jackets, and similar products.

Products made of #1 (PET) plastic should be recycled but not reused.

To use less PET plastic, consider switching to reusable beverage containers and replacing disposable food packaging with reusable alternatives.

#2 - HDPE (High-Density Polyethylene)

HDPE plastic is the stiff plastic used to make milk jugs, detergent and oil bottles, toys, and some plastic bags. HDPE is the most commonly recycled plastic and is considered one of the safest forms of plastic. It is a relatively simple and cost-effective process to recycle HDPE plastic for secondary use.

HDPE plastic is very hard-wearing and does not break down under exposure to sunlight or extremes of heating or freezing. For this reason, HDPE is used to make picnic tables, plastic lumber, waste bins, park benches, bed liners for trucks and other products which require durability and weather-resistance. It is also a popular material for recycled plastic raised garden beds.

Products made of HDPE are reusable and recyclable.

However, since only about 30-35% of HDPE plastic used in America gets recycled each year, it’s wise to use as little as possible. To cut down, consider replacing your disposable produce bags with reusable alternatives.

#3 – PVC (Polyvinyl Chloride)

PVC is a soft, flexible plastic used to make clear plastic food wrapping, cooking oil bottles, teething rings, children’s and pets’ toys, and blister packaging for myriad consumer products. It is commonly used as the sheathing material for computer cables, to make plastic pipes and parts for plumbing, and in garden hoses. Because PVC is relatively impervious to sunlight and weather, it is used to make window frames, garden hoses, arbors, raised beds and trellises.

PVC is dubbed the “poison plastic” because it contains numerous toxins which it can leach throughout its entire life cycle. Almost all products using PVC require virgin material for their construction; less than 1% of PVC material is recycled.

Products made using PVC plastic are not recyclable. While some PCV products can be repurposed, PVC products should not be reused for applications with food or for children’s use.

To avoid items made with PVC plastic, consider replacing plastic food wrap with reusable beeswax wraps; plastic toys with reclaimed wool stuffed animals; and your PVC garden hose with a Drinking Water Safe Garden Hose.

#4 – LDPE (Low-Density Polyethylene)

LDPE is often found in shrink wraps, dry cleaner garment bags, squeezable bottles, and the type of plastic bags used to package bread. The plastic grocery bags used in most stores today are made using LDPE plastic. Some clothing and furniture also uses this type of plastic.

LDPE is considered less toxic than other plastics, and relatively safe for use. It is not commonly recycled, however, although this is changing in many communities today as more plastic recycling programs gear up to handle this material. When recycled, LDPE plastic is used for plastic lumber, landscaping boards, garbage can liners and floor tiles. Products made using recycled LDPE are not as hard or rigid as those made using recycled HDPE plastic.

Products made using LDPE plastic are reusable, but not always recyclable. You need to check with your local collection service to see if they are accepting LDPE plastic items for recycling.

To cut down on the amount of LDPE that you consume, try replacing your plastic grocery bags with fabric alternatives and taking a cloth bag to your local bakery the next time you buy a loaf of bread. You can also replace plastic sandwich bags with platinum silicone alternatives, which are heat safe.

#5 – PP (Polypropylene)

Polypropylene plastic is tough and lightweight, and has excellent heat-resistance qualities. It serves as a barrier against moisture, grease and chemicals. When you try to open the thin plastic liner in a cereal box, it is polypropylene. This keeps your cereal dry and fresh. PP is also commonly used for disposable diapers, pails, plastic bottle tops, margarine and yogurt containers, potato chip bags, straws, packing tape and rope.

Polypropylene is recyclable through some curbside recycling programs, but only about 3% of PP products are currently being recycled in the US. Recycled PP is used to make landscaping border stripping, battery cases, brooms, bins and trays. However, #5 plastic is today becoming more accepted by recyclers.

PP is considered safe for reuse. To recycle products made from PP, check with your local curbside program to see if they are now accepting this material.

To cut down on how much PP you consume, opt for reusable straws instead of plastic ones, reusable water bottles, and cloth diapers.

#6 – PS (Polystyrene)

Polystyrene is an inexpensive, lightweight and easily-formed plastic with a wide variety of uses. It is most often used to make disposable styrofoam drinking cups, take-out “clamshell” food containers, egg cartons, plastic picnic cutlery, foam packaging and those ubiquitous “peanut” foam chips used to fill shipping boxes to protect the contents. Polystyrene is also widely used to make rigid foam insulation and underlay sheeting for laminate flooring used in home construction.

Because polystyrene is structurally weak and ultra-lightweight, it breaks up easily and is dispersed readily throughout the natural environment. Beaches all over the world have bits of polystyrene lapping at the shores, and an untold number of marine species have ingested this plastic with immeasurable consequences to their health.

Polystyrene may leach styrene, a possible human carcinogen, into food products (especially when heated in a microwave). Chemicals present in polystyrene have been linked with human health and reproductive system dysfunction.

Recycling is not widely available for polystyrene products. Most curbside collection services will not accept polystyrene, which is why this material accounts for about 35% of US landfill material. While the technology for recycling polystyrene is available, the market for recycling is small. Awareness among consumers has grown, however, and polystyrene is being reused more often. While it is difficult to find a recycler for PS, some businesses like Mailboxes Etc. which provide shipping services are happy to receive foam packing chips for reuse.

Polystyrene should be avoided where possible.

To eliminate polystyrene from your trash, try a reusable coffee cup, compostable or reusable picnic cutlery, and stainless steel takeaway containers.

#7 – Other (BPA, Polycarbonate and LEXAN)

The #7 category was designed as a catch-all for polycarbonate (PC) and “other” plastics, so reuse and recycling protocols are not standardized within this category. Of primary concern with #7 plastics, however, is the potential for chemical leaching into food or drink products packaged in polycarbonate containers made using BPA (Bisphenol A). BPA is a xenoestrogen, a known endocrine disruptor.

Number 7 plastics are used to make baby bottles, sippy cups, water cooler bottles and car parts. BPA is found in polycarbonate plastic food containers often marked on the bottom with the letters “PC” by the recycling label #7. Some polycarbonate water bottles are marketed as ‘non-leaching’ for minimizing plastic taste or odor, however there is still a possibility that trace amounts of BPA will migrate from these containers, particularly if used to heat liquids.

A new generation of compostable plastics, made from bio-based polymers like corn starch, is being developed to replace polycarbonates. These are also included in category #7, which can be confusing to the consumer. These compostable plastics have the initials “PLA” on the bottom near the recycling symbol. Some may also say “Compostable.”

#7 plastics are not for reuse, unless they have the PLA compostable coding. When possible it is best to avoid #7 plastics, especially for children’s food. Plastics with the recycling labels #1, #2 and #4 on the bottom are safer choices and do not contain BPA. PLA coded plastics should be thrown in the compost and not the recycle bin since PLA compostable plastics are not recyclable.

The plastics industry has conformed to regulations by applying the required codes to consumer products, but it is up to individuals to read and understand the codes. By understanding these simple classifications, we can best use plastics to our advantage while minimizing the health and disposal issues that may otherwise arise.

To avoid chemicals leaking into your foods from food packaging, try going homemade and storing your leftovers (or your lunches) in platinum silicone or stainless steel.

source:

https://learn.eartheasy.com/articles/plastics-by-the-numbers/